cotton picking machine mechanism

You can view this article in more than one different formats. This Invention relates to a machine for gathering cotton from growing plants of the type employing banks of opposed rotatable and reciprocable picking needles and it has particular reference to such a machine of ready portability and compactness and whose picking mechanisms will have no damaging effect on the cotton or plant foliage.

COTTON PICKERS CONSTRUCTION AND WORKING PRINCIPLES.

. At present most of the cotton picking machines in the market use high-speed airflow to. It is equipped with a bigger hopper which can extend the picking time greatly and boast large capacity in the field. There are two type of mechanical harvesting equipment popularly known as cotton.

Mechanical harvesting of cotton is widely used in USA Russia Egypt etc. The inventive harvesting apparatus includes a camera 1 with double walls 2 between which circulates magnetic fluid 3 is used as a working body of selectively acting on fruit boxes with cotton 8 cotton Bush 9 in the density changes under the influence of magnetic fields from the set in the. Easily pickingsave the labour cost.

Related

US Legal Forms fulfills the needs of Virginia Cotton Picking Machinery better than the competition. Our firm specializes in providing an excellent range of Cotton Picking Machines. Science 27 Mar 1942 Vol 95 Issue 2465 p.

Cotton picking machine is designed for cotton picking it can fulfill the cotton-picking operation in 6610cm or 688cm width of cotton planting mode. Benefit from the online library of 85000 state-specific forms and form packages that you can edit and eSign online. Some early prototypes tried to harvest with pneumatic mechanisms some tried to adopt threshing machines others tried static electricity or mechanical fingers.

-I- ý 1 laim. Or a person who picks ripe cotton fibre from the plants. Early Cotton Harvesting Machine In 1850 the first cotton harvesting machine was patented.

This picking machine is manufactured with quality tested material and advanc. Cotton picking machine mechanism Tuesday May 31 2022 Edit. Manual harvestingpicking of cotton is quite labour intensive operation.

V The object of this invention is to provide certain new and useful improvements in the cotton picking machines of the type disclosed in our Letters Patent No. 1894198 issued January 10 1933 and it especially has for Its object to provide the picking mechanism with a rain-proof housing having quickly removable lids to enable one to have instant access to the interior of. A cotton ginmeaning cotton engineis a machine that quickly and easily separates cotton fibers from their seeds enabling much greater productivity than manual cotton separation.

The cotton picker is either a machine that harvests cotton in a way that reduces harvest time. High and new technologies are widely used in the self-propelled picker. In many societies like America slave and serf labor was utilized to pick the cotton increasing the plantation owners profit margins See Trans-Atlantic Slave Trade.

Cotton picking machine Easy for handlingIt required 128 battery powerIt can pick up cotton 150 kg per day but it depend upon working efficiency. Enter the page number Enter the page number. Zhejiang Ocean University Zjou Zhoushan China.

Green Revolution Agro Science MIDC Wardha D-40 Industrial Area MIDC Wardha MIDC Wardha - 442001 Dist. Then over the next century over 1800 patents were issued for cotton harvesting schemes. T he pickin machine Jforming the subject matter of this invention is designed to at ford a device in which certain vegetable products may be picked from the plants as for instance cotton or the like and especially where it is desired to pass the materials through a suction device as a fan or blower without the danger of tearing or breaking the fibrous portions of certain kinds ot.

Agricultural machinery and can be used in cotton-picking machines. It requires 2-3 pickings and sometimes even more. Steel Oil and Labor.

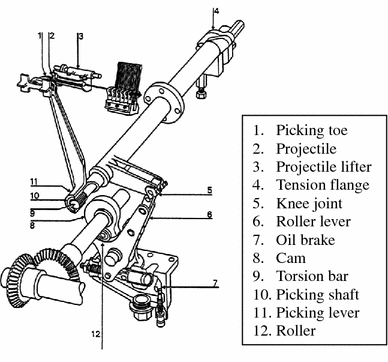

Cotton Picking manipulator Mechanism design Working space Optimized design. Design of Cotton Picking Manipulator. The objects of the invention hereinbefore enumerated as well as other and lesser objects are preferably applied as improvements on a cotton picking machine whose construction embodies a preliminary cotton cleaning mechanism to which the picked cotton is subjected prior to its delivery to suitable receptacles suspended rearwardly of the machin and with these objects in.

Ji Fulu li xiu. US Legal Forms has been providing legal forms and form packages to consumers small businesses and attorneys for almost 25 years.

Picking Mechanism On Projectile Weaving Machine Weaving Machine Weaving Industrial Fabric

How Do Cotton Harvesting Machines Work

Rubber Finger Harvest Mechanisms In Mcclendon Heads Disk Drive Left Download Scientific Diagram

International Harvester Cotton Harvesters Octane Press

Failure Analysis Of Torsion Bar Of Projectile Weaving Machine Springerlink

Schematic Diagram 7 Wheel Take Up Mechanism Cotton Weaving Weaving Loom

Beat Up Mechanism In Weaving Weaving Shuttle Loom Motion

5 Wheel Take Up Mechanism 5th Wheels Weaving Machine Weaving

Machines Free Full Text Working Speed Analysis Of The Gear Driven Dibbling Mechanism Of A 2 6 Kw Walking Type Automatic Pepper Transplanter Html

Cotton Harvesting Wessels Living History Farm

Agronomy Free Full Text Evaluation Of Autosteer In Rough Terrain At Low Ground Speed For Commercial Wild Blueberry Harvesting Html

Positive Tappet Shedding Mechanism Positive And Negative Positivity Negativity

Negative Tappet Shedding Mechanism Spinning Yarn Weaving Different Types Of Fabric

Grain Storage Techniques Grain Harvesting Threshing And Cleaning Technical Alternatives

Cotton Picker Mechanism Photograph Wisconsin Historical Society

Spinning Machines An Overview Sciencedirect Topics

How Combine Harvesters Work Explain That Stuff

Selection Of Cotton Harvesting Mechanism Results And Discussion Circular Economy For The Management Of Operations

How Do We Pick Cotton Version 2 Baler Pickers Youtube